VTube-LASER's UNMATCHED Measuring Concepts

|

VTube-LASER can do some things that other measuring centers cannot or will not do:

|

|

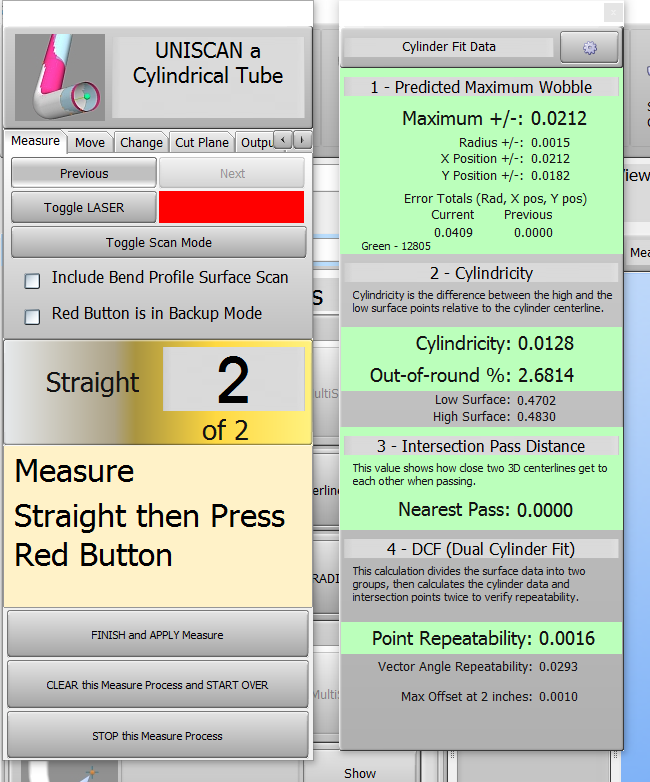

Five-Level Cylinder Fit Check

VTube-LASER uses a unique Cylinder Fit qualification method to help the user know that the measurement of each straight is good in real-time. Each tube straight is required to pass up to 5 levels of real-time qualification checks before it's scanned data is accepted as good.

|

Cool Invention #1: DCF (Dual Cylinder Fit)

|

The VTube-LASER DCF (Dual Cylinder Fit) feature is an invention that makes a huge difference in repeatability and reproducibility by measuring every tube twice internally when you measure it the first time.

VTube-LASER can use DCF because it uses laser surface scanners to take in huge amounts of tube surface point data that can then be broken down into two sub-groups for automatic comparison to each other. If the calculated data is too far apart, then VTube asks you to re-scan the straight. Other systems cannot easily perform DCF calculations - because they don't use surface laser scanners like VTube-LASER. |

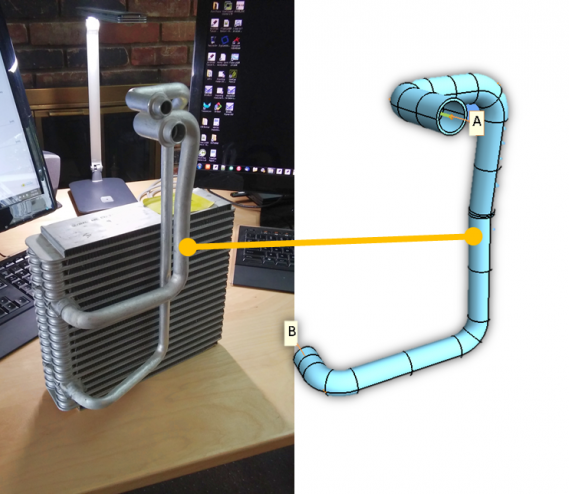

Cool Invention #2: DCP (Diameter Cut Plane)

|

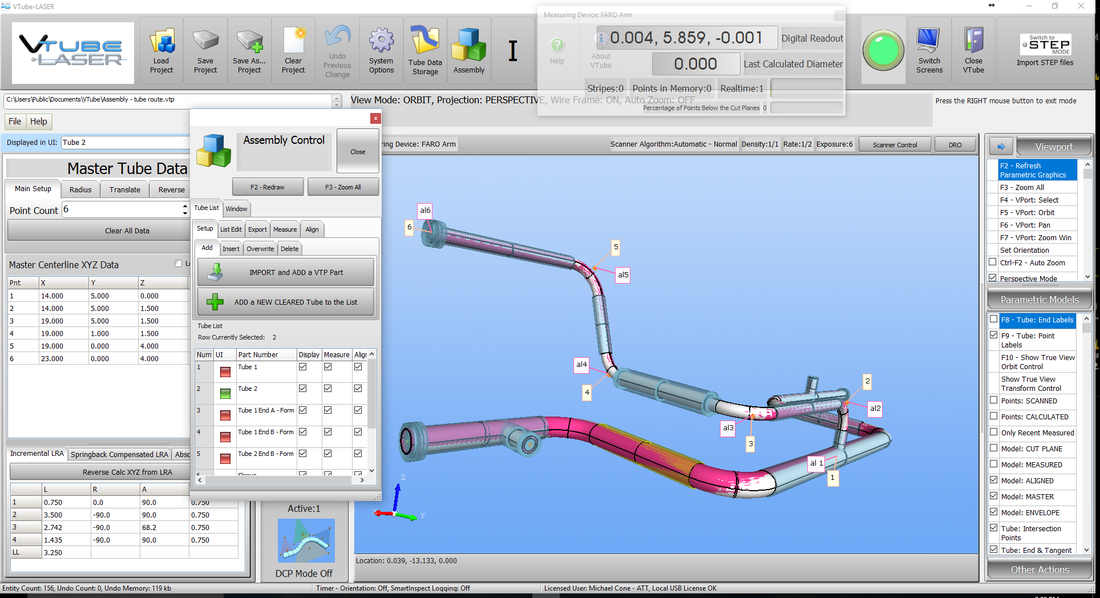

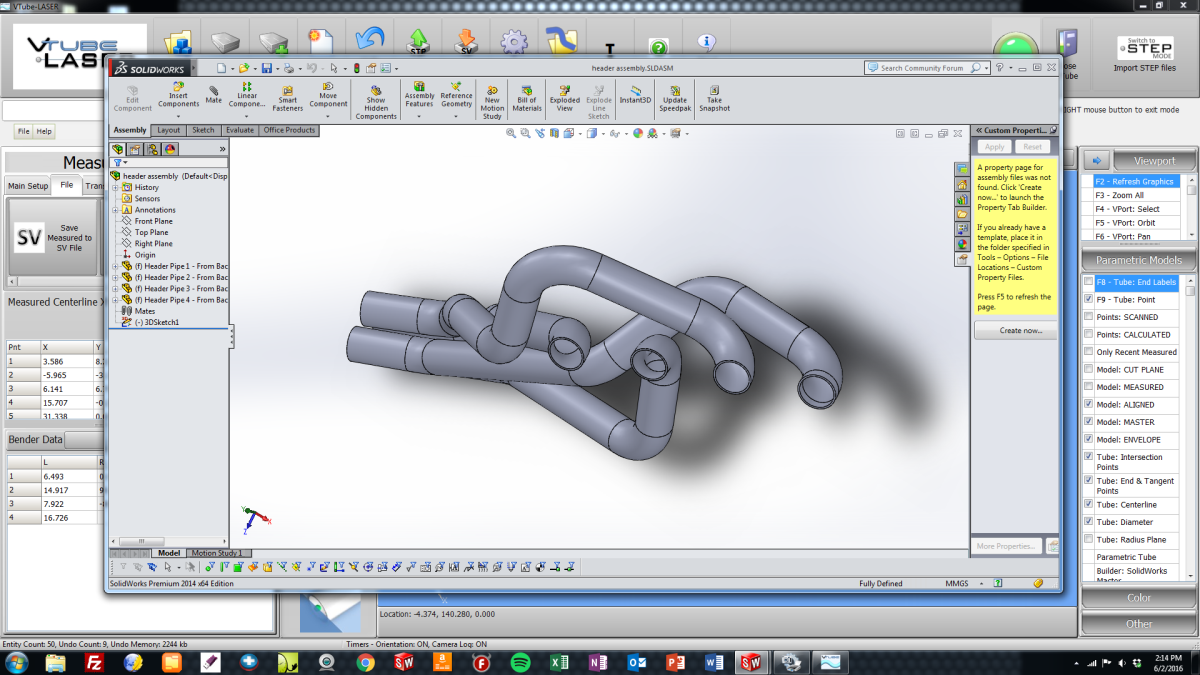

Our customer, Holley MSD, counts on the VTube-LASER DCP (Diameter Cut Plane) feature to measure their high-performance Hooker Blackheart exhaust systems. Our AIM Machine customers use it to effectively measure small bent wire shapes that turn back on themselves.

DCP is an invention that makes measuring in tight spaces in assemblies or small parts that twist back on themselves possible with a scanner. The idea is to allow VTube-LASER to keep only the first object it comes to along the axis of the probe spindle - and exclude any laser point that is too far from that first point. Not only does this help in crowded assemblies, but it also has the secondary benefit of throwing potential flyers out of the scan data. Other systems just don't have this kind of capability - because they require that you surround the tube (fork probe), or they try to sort out assemblies for you (camera systems). |