HEXAGON Absolute Arms: State-of-the-art LASER Scanning

|

|

We've performed months of tests on the HEXAGON Absolute Arm with integrated scanner. The test arm was a 7535 SI (3.5 meter arm).

Our tests showed that the HEXAGON Absolute Arm with Integrated scanner has one of the best scanner technologies of its type in the industry. For example, it is important in the tube fab industry that the scanner handles various types of surface reflectivity for cylinders well. This scanner-arm combination does exactly that. We found that this scanner technology avoids "flyers" (detected surface points for a non-existent surface) from high-reflectivity surfaces very well. We've come to trust it as a reliable scanner technology, and wholeheartedly recommend it to tube fabrication customers. |

Several Arm Lengths

|

HEXAGON offers an incredible number of length choices - 6 of them! You can purchase from 2.0 meter volume (the diameter of the sphere of reach of the arm) to 4.5 meter volume arm.

This is how we recommend you choose an arm length: Calculate the longest bent tube that you need to measure then add a half a meter to that value to get the arm length. For example, if your longest bent tube is 118", then we convert that to 3 meters, then add 0.5 meters to get a recommended arm length of 3.5 meters. The longest arm (the 4.5 meter), can easily handle a 12-foot long tube shape. You can also add our TRAX system to extend the arm reach up to 12 feet further than the arm volume. A 4.5 meter arm with a 12 foot TRAX unit can measure a 24 foot tube with one leapfrog move. |

|

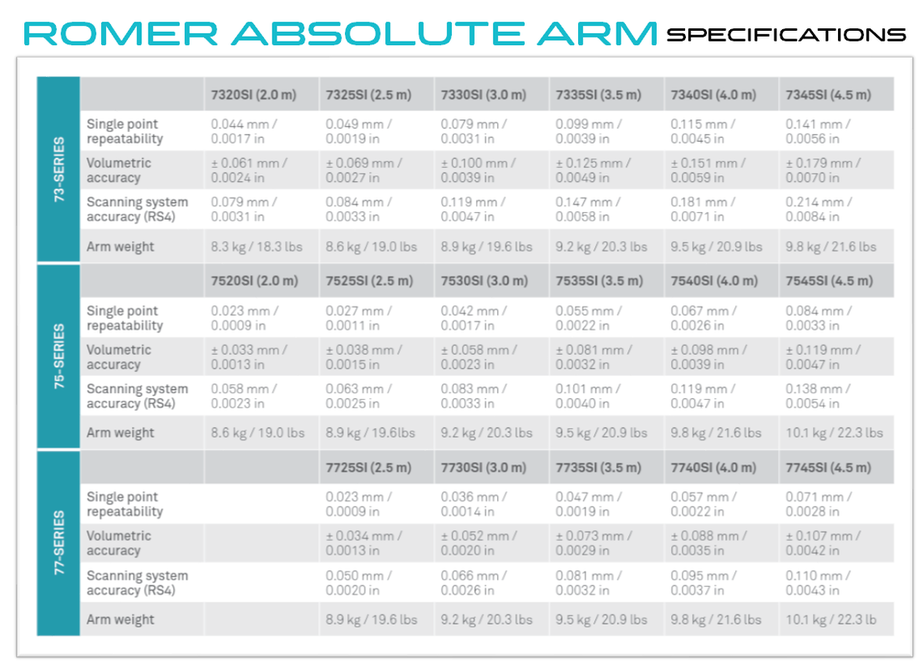

High Accuracy with 3 Levels of Arms

HEXAGON offers three levels of arms. They are 73, 75, and 77. In most applications the 73 series is more than accurate enough for tube fabrication applications. But if you need more, then you can opt for one of the more accurate models.

This chart gives you point (ball probe) and scanning accuracy of each system:

This chart gives you point (ball probe) and scanning accuracy of each system:

You can download the brochure that has the data shown above.

ROMER GridLOK for Large-volume Measurements

|

ROMER offers advanced technology like GridLOK for measuring extra large volume parts accurately.

This concept allows the ROMER RDS system to locate the arm position and orientation in space by touching calibrated conical seats that are embedded into the floor surface. You can move the arm at any time, then locate three conical seats, and GridLOK will automatically re-position the coordinate system based on the new arm position. |

|